Zero Waste in Real Estate: Design and Operations

Operational Strategies for Waste Minimization

Waste Reduction Strategies in Construction

Implementing effective waste reduction strategies during the construction phase of a real estate project is crucial. This involves meticulous planning, sourcing materials with minimal packaging, and utilizing construction techniques that minimize material waste. Careful pre-construction planning, including accurate material estimations, and the use of prefabricated components can significantly reduce the volume of waste generated on-site. Furthermore, fostering a culture of waste awareness among construction personnel through training and clear communication protocols is essential for long-term success.

Procurement and Material Selection

Responsible procurement practices play a vital role in waste minimization. Choosing materials with minimal packaging and prioritizing recycled or reused materials over virgin resources is key. This approach not only reduces waste but also fosters sustainability and environmental responsibility. Collaborating with suppliers who share these values can drive systemic change within the supply chain, leading to a more sustainable building industry.

Prioritizing durable, long-lasting materials over cheaper, disposable options can also significantly reduce the overall waste generated throughout the building's lifecycle. This proactive approach reduces the need for replacements and repairs in the future, minimizing the long-term environmental impact.

On-Site Waste Management Systems

A well-structured on-site waste management system is critical for effective waste minimization. This includes clearly defined waste streams, proper segregation and labeling of different waste types, and the implementation of dedicated recycling and composting programs. Regular audits and reviews of the waste management system are crucial for identifying areas for improvement and ensuring ongoing effectiveness. Investing in efficient waste collection and transportation systems can further streamline the process and reduce the environmental footprint.

Reuse and Recycling Programs

Actively promoting the reuse and recycling of construction and demolition debris is essential. Establishing clear protocols for the collection and processing of recyclable materials, such as wood, metal, and concrete, can significantly reduce landfill waste. Partnering with local recycling facilities and establishing clear guidelines for the handling of reusable materials are important steps in maximizing the reuse potential of construction materials.

Employee Training and Awareness

Effective waste minimization requires a cultural shift towards sustainability. Comprehensive training programs for all employees, from construction workers to project managers, are crucial for fostering a shared understanding of waste reduction principles. This training should cover waste segregation protocols, proper disposal methods, and the importance of responsible material handling. Promoting a culture of waste awareness and accountability among all stakeholders can significantly contribute to the overall success of waste minimization initiatives in the real estate sector.

Material Selection and Sourcing for Reduced Impact

Material Selection Criteria

A crucial aspect of any product development or manufacturing process is the careful selection of materials. This involves evaluating various factors to ensure the chosen material meets the specific requirements of the application. Material properties, such as strength, durability, and resistance to environmental factors, are paramount. Consideration must also be given to the material's cost-effectiveness, availability, and potential impact on the environment.

Different materials offer varying degrees of performance characteristics, and the optimal choice depends entirely on the intended use. For instance, a high-strength metal might be preferable for structural components, whereas a lightweight plastic could be more suitable for packaging applications. Understanding these trade-offs is essential for informed decision-making.

Sourcing Strategies

Reliable sourcing is equally critical to a successful material acquisition process. This involves identifying reputable suppliers who can provide consistent quality materials at competitive prices. Thorough due diligence, including supplier audits and performance evaluations, is essential to mitigate risks and ensure supply chain robustness. Maintaining strong relationships with suppliers is vital for long-term success and potentially securing preferential pricing or early access to new materials.

Sustainability Considerations

In today's environmentally conscious world, sustainable material sourcing practices are increasingly important. This includes evaluating the environmental impact of the extraction, processing, and manufacturing of the chosen material. Prioritizing recycled or renewable materials can significantly reduce the environmental footprint of the product, aligning with broader sustainability goals and potentially opening up new avenues for ethical procurement.

Companies should also consider the lifecycle of the material, from its initial use to its eventual disposal. Minimizing waste and maximizing recycling potential are essential components of a sustainable sourcing strategy.

Cost Analysis and Budgeting

Material costs can significantly impact the overall profitability of a project. Careful cost analysis is necessary to evaluate the total cost of ownership, including not only the purchase price but also potential transportation, storage, and processing expenses. Understanding the long-term cost implications is critical for effective budgeting and financial planning. Negotiating favorable pricing and leveraging bulk purchasing discounts can help optimize material costs without compromising quality.

Quality Control and Assurance

Ensuring the quality of the sourced materials is paramount. Implementing rigorous quality control measures throughout the procurement process is essential to avoid defects and ensure the product meets the required specifications. Testing and inspection procedures should be clearly defined to maintain consistent quality standards and minimize product failures. This includes establishing clear acceptance criteria for incoming materials and conducting regular quality audits of suppliers.

Regulatory Compliance

Adhering to relevant industry regulations and standards is critical in material selection and sourcing. Understanding and complying with safety regulations, environmental standards, and ethical sourcing guidelines is essential to avoid legal issues and reputational damage. This includes obtaining necessary certifications and ensuring materials meet specific safety requirements. Thorough research and due diligence are crucial to identifying and navigating potential compliance challenges.

Risk Management Strategies

Supply chain disruptions and material shortages can have a significant impact on production schedules and project timelines. Developing robust risk management strategies is essential to mitigate these potential disruptions. This includes diversifying material sources, establishing contingency plans, and building strong relationships with multiple suppliers to ensure a secure and reliable supply chain. Having a backup plan in place for unexpected events can prevent delays and maintain project momentum.

Adopting a mobile-first design philosophy isn't just about creating smaller versions of desktop websites; it's a fundamental shift in perspective. It compels designers to prioritize the user experience on the smallest screen first, ensuring that the core functionality and information architecture are easily accessible and intuitive on a mobile device. This approach often leads to a more streamlined and user-friendly experience across all platforms, as the initial focus on mobile forces a simplification of design and content.

Read more about Zero Waste in Real Estate: Design and Operations

Hot Recommendations

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

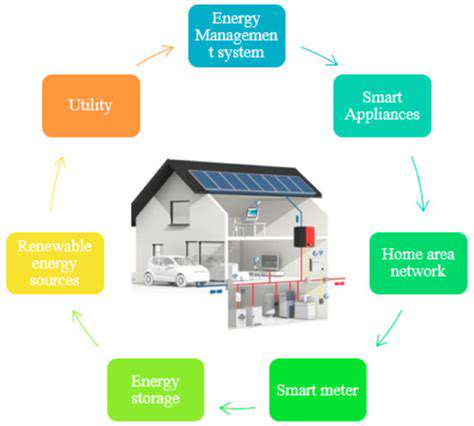

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy