AI and Machine Learning in Smart Building Management Systems

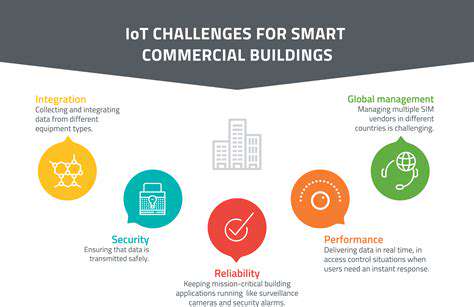

Modern predictive maintenance harnesses the power of artificial intelligence and machine learning to foresee equipment failures before they disrupt operations. By meticulously analyzing data streams from sensors, operational logs, and historical performance metrics, these intelligent systems detect subtle patterns and irregularities that may indicate impending issues. This forward-thinking methodology enables strategically timed maintenance, dramatically reducing unplanned downtime while extending equipment longevity. The fundamental shift involves transitioning from reactive repairs - addressing problems only after breakdowns occur - to a preventative paradigm that slashes the likelihood of expensive failures.

Proactive Troubleshooting with AI

AI-driven troubleshooting transcends basic problem identification by delivering concrete, actionable solutions. Advanced algorithms process live data feeds to precisely diagnose malfunctions, offering comprehensive assessments of underlying causes. This surgical precision empowers maintenance teams to implement targeted solutions, accelerating resolution times and improving repair quality. When combined with predictive capabilities, this proactive stance yields substantial operational savings while boosting overall equipment effectiveness.

Machine Learning Models for Anomaly Detection

Sophisticated machine learning architectures, including neural networks and support vector machines, serve as the backbone for identifying operational anomalies. These models train on historical datasets, developing the ability to spot deviations from established performance baselines. Through continuous real-time monitoring, the system flags irregularities, giving maintenance personnel early warnings about potential concerns. This vigilant approach to anomaly detection forms the cornerstone of effective predictive maintenance, enabling prompt corrective actions that mitigate failure impacts.

Real-World Applications and Benefits

The implementation of predictive maintenance and proactive troubleshooting is revolutionizing diverse industrial sectors. Manufacturing facilities, utility networks, and transportation systems alike are experiencing operational transformations. Tangible benefits include dramatic reductions in unscheduled downtime, slashed maintenance expenditures, prolonged equipment service life, and enhanced workplace safety. These AI-powered solutions don't just respond to problems - they prevent them, creating leaner, more sustainable business operations that translate to improved profitability and productivity.

The Future of Maintenance: AI Integration

Maintenance strategies will become increasingly intertwined with artificial intelligence capabilities. As sensor technologies grow more sophisticated and machine learning algorithms achieve greater refinement, predictive accuracy will reach unprecedented levels. This evolution will enable even more precise failure forecasting and optimized maintenance scheduling. The widespread adoption of AI in maintenance operations promises to redefine industrial efficiency standards, ushering in an era of unprecedented cost-effectiveness. This technological shift will also create opportunities for enhanced automation across numerous industrial processes.

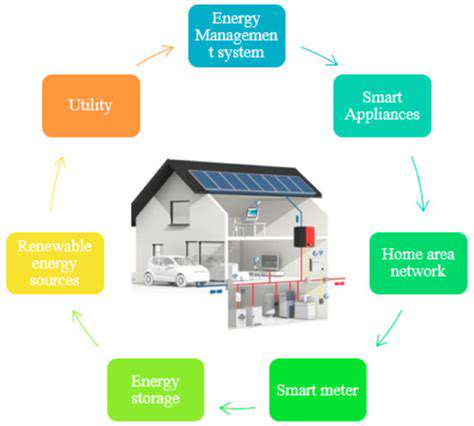

Intelligent Energy Management for Sustainability

Optimizing Energy Consumption

Contemporary intelligent energy management solutions play a pivotal role in maximizing energy efficiency across multiple industries. These systems employ cutting-edge technologies and advanced analytics to detect energy waste, identify inefficiencies, and implement precise corrective measures. This proactive strategy delivers substantial cost savings while making meaningful contributions to environmental conservation through reduced carbon footprints. Smart sensor networks and automated control mechanisms enable continuous monitoring and dynamic adjustments, ensuring optimal energy utilization at all times.

Predictive Maintenance and Proactive Repairs

Predictive maintenance proves particularly valuable in safeguarding energy infrastructure from catastrophic failures. By evaluating historical performance data alongside current operational metrics, intelligent systems can forecast potential equipment issues and schedule preventative maintenance. This forward-looking approach maintains equipment at peak operating conditions, thereby maximizing energy efficiency while preventing costly outages. Early identification of developing problems facilitates timely interventions, minimizing both repair expenses and potential energy production losses.

Real-Time Monitoring and Control

Continuous monitoring and adaptive control represent critical elements of modern energy management systems. Sophisticated sensor arrays coupled with powerful analytics platforms provide comprehensive visibility into energy usage patterns, enabling immediate detection of irregularities. This granular monitoring capability facilitates rapid response to changing conditions, maintaining ideal energy efficiency through dynamic adjustments. The systems' ability to process live data streams allows for continuous optimization of energy consumption in fluctuating operational environments.

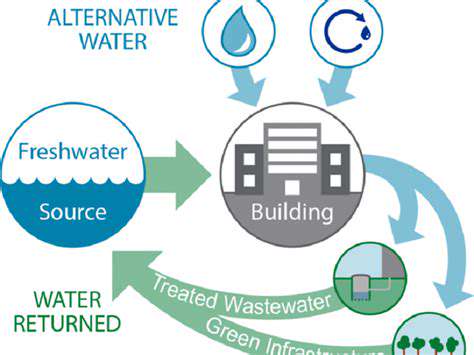

Integration of Renewable Energy Sources

Seamless incorporation of renewable energy generation represents a key advantage of intelligent management systems. These solutions optimize the utilization of intermittent renewable sources like solar and wind power by forecasting generation capacity and aligning it with demand patterns. Advanced management platforms maximize the exploitation of clean energy resources, significantly reducing dependence on conventional power generation. This capability contributes to grid stability while supporting environmental sustainability goals through reduced fossil fuel consumption.

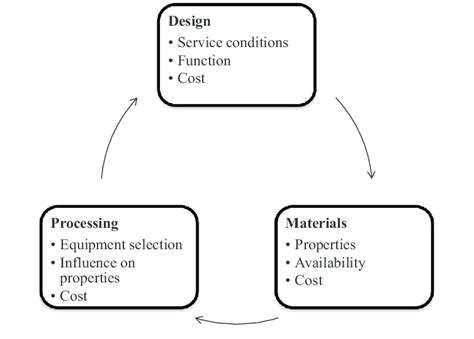

Data-Driven Decision Making

Modern energy management relies fundamentally on comprehensive data analysis. By aggregating and processing vast datasets from multiple sources, these systems uncover valuable insights, trends, and patterns that would otherwise remain hidden. This evidence-based approach informs strategic decisions regarding energy usage, infrastructure upgrades, and technology investments. The resulting intelligence proves invaluable for developing robust energy optimization strategies and achieving substantial cost reductions.

Improved Energy Security and Resilience

Intelligent energy management significantly enhances operational reliability and system robustness. Through strategic energy consumption optimization, these systems decrease dependence on external power sources while improving supply consistency. The adaptive nature of these solutions strengthens grid resilience during disruptions or extreme weather events, ensuring uninterrupted energy availability. This approach fosters a more secure and stable energy infrastructure, effectively mitigating operational risks and guaranteeing reliable power distribution.