IoT Sensors Revolutionizing Building Management

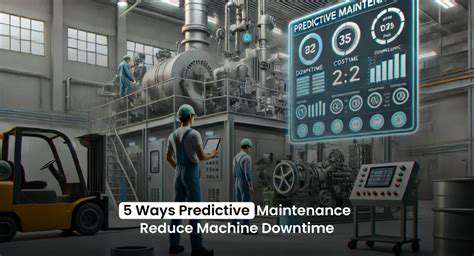

Predictive maintenance is revolutionizing industrial operations by moving away from reactive maintenance strategies to proactive ones. Instead of waiting for equipment failures to occur, predictive maintenance utilizes data analysis and advanced algorithms to anticipate potential issues and schedule maintenance before they cause significant downtime and costly repairs. This shift towards a proactive approach enhances operational efficiency and reduces overall maintenance costs.

Data Collection and Analysis: The Cornerstone of Predictive Maintenance

A critical component of successful predictive maintenance is the robust collection and analysis of data. This data can encompass a wide range of information, including sensor readings, vibration patterns, temperature fluctuations, and operational parameters. Sophisticated algorithms and machine learning models are then employed to process this data and identify anomalies that signal potential equipment failures.

Analyzing this data effectively is paramount to identifying the root cause of potential problems and avoiding costly failures. Accurate data analysis forms the bedrock of successful predictive maintenance strategies.

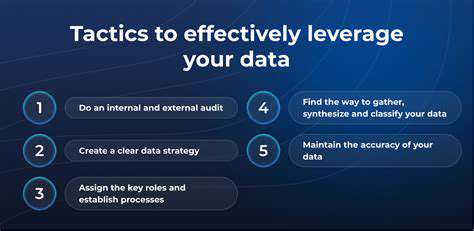

Implementing Predictive Maintenance: A Step-by-Step Guide

Implementing predictive maintenance involves several key steps, including defining the scope of the program, selecting appropriate sensors and data collection systems, developing predictive models based on collected data, and establishing a clear maintenance schedule. This process requires careful consideration of the specific needs and characteristics of the equipment being monitored.

Enhanced Equipment Reliability and Reduced Downtime

Predictive maintenance strategies effectively improve equipment reliability by identifying and addressing potential issues before they escalate. This proactive approach minimizes unplanned downtime, maximizing operational efficiency and output. Predictive maintenance helps businesses optimize their production schedules and maintain consistent output.

Cost Savings and Return on Investment (ROI)

Predictive maintenance offers a substantial return on investment by reducing the frequency of unplanned maintenance events, minimizing downtime, and extending the lifespan of equipment. These cost-saving benefits can be significant, as they directly impact production costs, labor expenses, and repair expenses.

Predictive maintenance solutions often provide a tangible return on investment (ROI) through improved operational efficiency and reduced maintenance costs. This ROI is a key driver in the adoption of predictive maintenance strategies by businesses across various industries.

Integration with Other Industrial Technologies

Predictive maintenance can be seamlessly integrated with other industrial technologies, such as the Internet of Things (IoT) and Industrial Internet of Things (IIoT) platforms. This integration allows for real-time data collection and analysis, further enhancing the effectiveness and efficiency of predictive maintenance programs. Data-driven insights can be leveraged to drive improvements in operational efficiency.

Future Trends in Predictive Maintenance

Future trends in predictive maintenance are likely to involve the increasing use of artificial intelligence (AI) and machine learning (ML) technologies. These advancements will allow for more sophisticated data analysis, enabling the identification of even subtle patterns and anomalies in equipment performance. Advanced AI will allow for more accurate predictions of potential equipment failures, further optimizing maintenance schedules and reducing downtime.

A visual inspection of the coolant reservoir is a crucial first step in maintaining your vehicle's cooling system. Look for signs of low coolant levels, which can indicate a leak somewhere in the system. A consistently low level, or one that fluctuates drastically, demands further investigation. Pay close attention to the color of the coolant; a discolored or unusual color, such as a dark brown or even pink, might suggest a problem with the engine's internal components and necessitates a visit to a mechanic.