Modular Sustainable Construction: Scalability and Speed

The construction industry is undergoing a significant transformation, with prefabricated housing gaining increasing popularity. This innovative approach to building involves constructing homes in a factory setting, utilizing standardized components and precise engineering. This method offers numerous advantages, from reducing construction time and costs to minimizing waste and environmental impact. Prefabrication allows for greater control over quality and consistency, resulting in more durable and energy-efficient homes. This approach is especially beneficial in areas with limited resources or skilled labor, enabling faster delivery of housing solutions.

Prefabricated homes often incorporate sustainable building materials and practices. These homes can be designed to meet or exceed energy efficiency standards, minimizing the environmental footprint of the building process. This focus on sustainability aligns with growing global concerns regarding climate change and resource depletion. The modular nature of prefabricated construction lends itself to customized designs, enabling homeowners to tailor their homes to specific needs and preferences.

Environmental Benefits of Prefabricated Construction

One of the most significant advantages of prefabricated construction is its reduced environmental impact. By minimizing on-site construction activities, prefabrication significantly reduces the amount of waste generated and the overall carbon footprint of the project. The standardized nature of prefabricated components allows for precise material usage, reducing material waste and promoting resource efficiency. This focus on sustainability aligns with the growing need for environmentally conscious building practices.

Prefabricated components are often manufactured using sustainable materials. The use of recycled materials and locally sourced components further minimizes the environmental impact of these homes. Construction time is also significantly reduced, leading to less disruption to the surrounding environment. The decreased need for transportation of materials further contributes to a lower carbon footprint compared to traditional construction methods.

Cost-Effectiveness and Efficiency

Prefabricated construction offers significant cost advantages over traditional methods. The factory-based production process allows for economies of scale, resulting in lower material and labor costs. The precise planning and standardized components minimize errors and rework, leading to reduced construction time and overall project costs. This efficiency translates to faster delivery of homes, which is particularly beneficial in rapidly developing regions or areas experiencing a housing shortage.

Prefabrication also streamlines the construction process, reducing the need for on-site coordination and management. This leads to improved project management and reduced delays. The predictability of prefabricated construction allows for more accurate cost estimations and better budget control. Furthermore, the use of advanced technologies and automation in prefabrication further enhances efficiency and accuracy in the construction process.

The Future of Prefabrication in Construction

The future of prefabricated housing appears bright, as the demand for sustainable and efficient building solutions continues to grow. Technological advancements in prefabrication are constantly improving design flexibility and construction techniques. The integration of 3D printing and other cutting-edge technologies promises to further revolutionize the construction industry. This innovative approach to construction is poised to play an increasingly important role in shaping the future of urban development and sustainable living.

The increasing awareness of environmental concerns and the need for efficient housing solutions will drive further adoption of prefabricated construction. The potential for customization, cost-effectiveness, and reduced environmental impact makes prefabrication an attractive alternative to traditional construction. The industry is poised to experience significant growth, contributing to the development of more sustainable and resilient communities in the years to come.

Prefabrication: A Key Enabler of Sustainable Practices

Prefabrication's Impact on Construction Efficiency

Prefabrication, the process of constructing components of a building off-site, is revolutionizing the construction industry. This approach drastically improves efficiency by allowing for controlled environments and specialized equipment, leading to faster assembly times on-site. By pre-assembling modules and systems in a factory setting, builders can streamline the construction process, minimizing delays and maximizing productivity. This ultimately translates to significant cost savings and reduced project timelines.

The inherent precision of off-site fabrication contributes to a higher quality of construction. Detailed plans and controlled environments minimize errors, leading to a more accurate and reliable final product. This precision also allows for better use of materials, further reducing waste and costs associated with on-site adjustments.

Prefabricated Building Materials and Technologies

A wide array of building materials and technologies are employed in prefabrication. From structural steel and concrete elements to pre-assembled roofing systems and complete interior modules, prefabrication encompasses a broad spectrum of construction components. This diversity allows for customization and adaptability to meet specific project requirements while maintaining the efficiency gains of prefabrication.

Advancements in 3D printing and robotic fabrication are further enhancing the potential of prefabrication. These technologies can create intricate designs and complex components with unprecedented accuracy, precision, and speed. This is leading to the development of more complex and efficient building designs in prefabrication.

Prefabrication's Role in Sustainability

Prefabrication plays a significant role in promoting sustainable construction practices. By reducing waste through precise material use and minimizing on-site disruption, prefabrication contributes to a more environmentally friendly approach to building. This reduction in waste not only benefits the environment but also reduces the financial burden on construction projects.

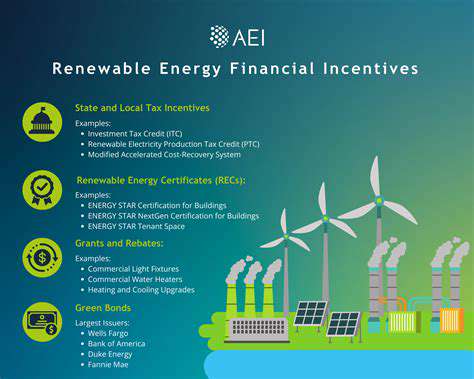

Prefabricated components can also be designed with sustainability in mind. Using recycled materials, incorporating renewable energy systems, and optimizing energy efficiency within the prefabricated modules are just a few examples of how prefabrication can contribute to a greener building industry.

Prefabrication and the Future of Construction

The future of construction is undeniably intertwined with prefabrication. The increasing demand for faster, more efficient, and sustainable building methods is driving the adoption of prefabrication techniques across various sectors. This trend is expected to continue, transforming the way buildings are designed, constructed, and managed. The potential for innovation and optimization is immense.

Prefabrication is not just about speed and efficiency; it's about creating a more resilient and adaptable construction industry. The ability to pre-assemble components in controlled environments allows for better quality control, reduced construction time, and optimized resource utilization.

Scalability: Meeting Growing Demand with Efficiency

Horizontal Scaling for Increased Capacity

Horizontal scaling, a fundamental aspect of modern application architecture, involves adding more resources, such as servers, to handle increased demand. This approach allows applications to grow proportionally to the demands placed upon them. Instead of relying on a single, powerful machine, horizontal scaling distributes the workload across a cluster of smaller, more manageable servers. This approach offers significant advantages in terms of resilience and fault tolerance, as the failure of one server does not necessarily bring down the entire system.

By distributing the workload, horizontal scaling ensures a smoother transition as demand increases, preventing bottlenecks and maintaining optimal performance. This approach is crucial for applications expected to experience substantial growth in user base or data volume over time.

Vertical Scaling: Enhancing Individual Server Resources

Vertical scaling involves increasing the resources of a single server, such as adding more RAM or processing power. While this approach can be effective for handling a moderate increase in demand, it has limitations in terms of scalability, as the resources of a single server are ultimately constrained. This method often proves less flexible compared to horizontal scaling in the face of substantial growth.

Load Balancing for Efficient Resource Utilization

Load balancing is a critical component of scalable systems. It intelligently distributes incoming requests across multiple servers, preventing any single server from becoming overloaded. Effective load balancing is essential for ensuring consistent response times and preventing performance bottlenecks, especially during periods of high traffic.

This strategic distribution of requests ensures that resources are utilized optimally, thereby maximizing application performance and responsiveness. Without load balancing, a surge in user activity can quickly overwhelm a single server, leading to decreased performance and a degraded user experience.

Database Scalability Strategies

Database scalability is a crucial aspect of application design, as databases often become the performance bottleneck in high-demand scenarios. Different database systems offer various scaling strategies, including sharding, which involves distributing data across multiple databases, and clustering, which allows multiple servers to cooperate to manage the database load.

Implementing appropriate database scaling strategies is essential to ensure data integrity and prevent performance degradation as the volume of data grows. Proper planning and implementation are critical to avoid data loss or system downtime, which can have a substantial impact on the overall application.

Caching Mechanisms for Improved Response Times

Caching mechanisms play a significant role in optimizing application performance by storing frequently accessed data in readily available locations. This localized storage drastically reduces the need to retrieve data from the primary data source, which significantly speeds up response times, especially for frequently accessed content. By caching frequently accessed data, applications can significantly reduce the load on the database and other backend systems.

Caching can significantly reduce database load, leading to improved application performance and responsiveness. This is especially critical for applications experiencing high traffic and demanding a high level of user interaction.

Monitoring and Optimization for Continuous Improvement

Continuous monitoring and optimization are essential for maintaining a scalable application. Monitoring tools track key performance indicators (KPIs), allowing for proactive identification of potential bottlenecks or performance issues. This proactive approach enables swift responses to emerging challenges and ensures that the application remains optimized for peak performance.

Regular performance analysis and adjustments are key to proactively addressing potential performance issues. Regular optimization ensures that the application remains efficient and responsive as demands evolve. This ongoing process is critical for maintaining user satisfaction and ensuring the longevity of the application.

Data-driven email personalization isn't just a trend; it's a fundamental shift in how businesses connect with their audience. Leveraging data allows marketers to move beyond generic messages and craft communications tailored to individual customer preferences, behaviors, and needs. By understanding the nuances of customer data, from purchase history to website interactions, businesses can create more relevant and engaging email experiences.

The Future of Green Building: Embracing Innovation

Modular Construction: A Key to Sustainable Solutions

Modular construction, a process where building components are prefabricated off-site, is rapidly gaining traction as a key strategy for achieving sustainability in the building sector. This method allows for greater control over material selection and waste reduction, as well as optimized resource utilization. Pre-fabrication enables precise material cutting and assembly, minimizing material waste and the environmental impact associated with on-site construction. By reducing the time spent on-site, modular construction also contributes to decreased energy consumption and lower carbon emissions during the construction phase.

The inherent efficiency of modular construction extends beyond material optimization. It facilitates the use of sustainable materials, from recycled aggregates and timber to advanced composite panels. This approach enables a greater focus on long-term performance and reduced embodied carbon throughout the building's life cycle, aligning with the principles of a truly sustainable building. The controlled environment of the factory setting ensures high-quality workmanship and adherence to precise specifications, leading to more durable and energy-efficient buildings.

Innovative Materials: Driving Green Building Practices

The evolution of green building is intricately linked to the development and application of innovative materials. Sustainable materials, such as recycled and bio-based products, are becoming increasingly prevalent in the construction industry. These materials often boast lower embodied carbon and offer enhanced performance characteristics, further contributing to the overall sustainability of the building. Innovative designs using these materials can dramatically reduce the environmental footprint of a building throughout its lifespan. The development of advanced composite materials, for example, allows for lighter yet stronger structures, potentially leading to reduced energy consumption for transportation and construction.

Beyond traditional materials, advancements in manufacturing processes are leading to the creation of new, sustainable building components. This includes the use of advanced insulation materials, high-performance windows, and energy-efficient systems. The focus is not just on reducing resource consumption but also on optimizing the performance of the building itself. This means minimizing energy use, managing water efficiently, and ensuring indoor environmental quality. These factors are essential for creating truly sustainable and resilient buildings.

Technological Advancements: Streamlining Sustainability

Technological advancements are playing a critical role in streamlining the process of sustainable construction. From 3D printing to advanced building information modeling (BIM), technology is transforming how buildings are designed, constructed, and managed. 3D printing, for example, offers the potential to create complex structures with minimal waste, accelerating the construction process, and offering greater design flexibility. BIM software tools facilitate better collaboration, enhancing communication and coordination among project stakeholders, which in turn leads to more efficient and sustainable outcomes. The integration of sensors and data analytics allows for real-time monitoring of building performance, enabling adjustments to optimize energy efficiency and resource utilization.

Smart building technologies, incorporating sensors, automation, and data analytics, are becoming increasingly sophisticated. These advancements enable real-time monitoring and control of building systems, optimizing energy consumption and resource use. This data-driven approach allows for continuous improvement in building performance and a reduction in environmental impact. The future of green building is deeply intertwined with the continued development and implementation of these technologies.