Smart Elevators: Efficiency and Predictive Maintenance

Predictive Maintenance: Proactive Solutions for Reduced Downtime

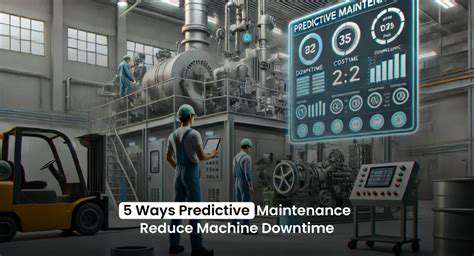

Understanding Predictive Maintenance

Predictive maintenance (PdM) is a proactive approach to equipment maintenance that focuses on preventing failures before they occur. Instead of relying on reactive maintenance, which addresses problems after they arise, PdM uses data analysis and advanced technologies to predict when equipment is likely to fail. This allows organizations to schedule maintenance activities in advance, minimizing downtime and maximizing equipment lifespan. This shift from reactive to proactive maintenance is crucial for optimizing operational efficiency and reducing overall costs.

Essentially, PdM utilizes various sensor data and other relevant information to identify patterns and anomalies that could indicate impending equipment failures. By analyzing these patterns, predictive models can forecast the likelihood of a failure and provide insights into the optimal time for maintenance intervention. This advanced approach to maintenance significantly reduces the risk of unexpected breakdowns and associated disruptions.

Data Collection and Analysis in PdM

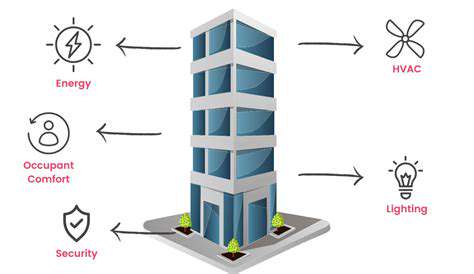

A critical component of predictive maintenance is the effective collection and analysis of data. This involves deploying sensors on equipment to monitor various parameters such as vibration, temperature, pressure, and energy consumption. The collected data is then processed and analyzed to identify patterns and deviations from normal operating conditions. This data-driven approach allows for a deeper understanding of equipment health and potential failure points.

Sophisticated algorithms and machine learning techniques are employed to analyze the vast amount of data collected. These techniques allow for the identification of subtle trends and anomalies that might not be apparent to human operators. This data analysis forms the basis for predictive models that forecast future equipment performance and potential failures, thus enabling proactive maintenance interventions.

Benefits of Implementing Predictive Maintenance

Implementing predictive maintenance offers a multitude of benefits to organizations. Reduced downtime is a significant advantage, as proactive maintenance scheduling minimizes the impact of unexpected equipment failures on production schedules and operational efficiency. Improved equipment lifespan is another key benefit, as preventive maintenance interventions can extend the operational life of equipment, reducing replacement costs and optimizing long-term investment.

Beyond these tangible benefits, predictive maintenance also results in improved safety standards. By identifying potential failures in advance, organizations can implement necessary safety precautions and prevent hazardous incidents. This proactive approach also leads to reduced maintenance costs in the long run, as preventative measures are often less expensive than repairing or replacing equipment after failure.

Technological Advancements in PdM

Technological advancements are driving the evolution of predictive maintenance. The increasing availability of affordable and sophisticated sensors, coupled with advancements in cloud computing and data analytics, are enabling more complex and accurate predictive models. These advancements are making PdM more accessible and impactful for businesses of all sizes.

The integration of Internet of Things (IoT) devices and real-time data streaming further enhances the capabilities of predictive maintenance. Real-time data analysis allows for immediate responses to potential issues, leading to even more effective and timely maintenance interventions. This continuous stream of data provides a comprehensive view of equipment health, enabling more accurate predictions and optimized maintenance strategies.

Challenges and Considerations in PdM Implementation

While predictive maintenance offers significant advantages, there are also challenges associated with its implementation. One key challenge is the need for substantial upfront investment in sensors, data analytics tools, and skilled personnel. Furthermore, the complexity of data analysis can require specialized expertise and potentially complex algorithms.

Data quality and reliability are also crucial factors. Inaccurate or incomplete data can lead to flawed predictions and ineffective maintenance strategies. Therefore, robust data collection and validation procedures are essential to ensure the accuracy and reliability of the predictive models. Implementing a robust data management strategy is critical to maximizing the success of any PdM initiative.

Smart ticketing systems offer a significant advancement in managing access to events, venues, and attractions. These innovative systems leverage technology to streamline the ticketing process, enhancing the overall experience for both customers and administrators. By eliminating the need for physical tickets, smart ticketing reduces the risk of lost or misplaced tickets and provides a more efficient and secure entry method. This digital approach also allows for real-time updates and management of ticket availability, minimizing potential issues and ensuring a smooth flow of customers.

Read more about Smart Elevators: Efficiency and Predictive Maintenance

Hot Recommendations

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy