Transition Pathways for Real Estate Decarbonization

Industrial Decarbonization: A Critical Component

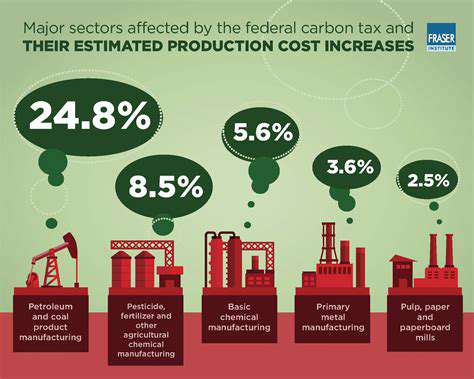

Construction materials like steel and cement account for about 10% of global emissions - roughly equivalent to all agricultural emissions combined. The real estate industry cannot achieve meaningful decarbonization without addressing its supply chain's carbon footprint. Emerging solutions include electric arc furnaces for steel recycling and carbon capture systems at cement plants.

Forward-thinking developers are now conducting whole-life carbon assessments before breaking ground, allowing them to identify and mitigate high-impact materials early in the design process.

Transportation Sector Integration

Location efficiency - how easily occupants can access amenities without driving - significantly impacts a property's carbon footprint. Transit-oriented developments that combine housing with retail and office space can reduce vehicle miles traveled by 20-40% compared to conventional sprawl. Some progressive projects now include EV charging infrastructure and micromobility hubs as standard features.

Energy Sector Transition

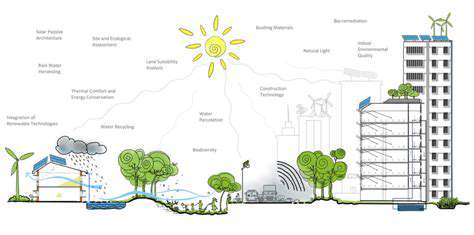

While renewable energy gets most attention, the real low-hanging fruit lies in reducing demand through better building design. Passive house principles can cut heating and cooling needs by 75% compared to conventional construction. When paired with on-site solar and battery storage, such buildings often achieve net-positive energy status.

Building and Infrastructure Decarbonization

The most sustainable building is often the one already standing. Deep energy retrofits of existing structures typically save 50-75% of the embodied carbon versus new construction. Techniques like adding exterior insulation and replacing fossil fuel systems with heat pumps are proving both environmentally and economically viable.

Decarbonization in Real Estate Operations

Property management practices significantly impact ongoing emissions. Implementing smart building systems can reduce energy waste by 15-30% through optimized HVAC scheduling and real-time performance monitoring. Some landlords now tie leasing terms to sustainability metrics, creating shared incentives for emission reductions.

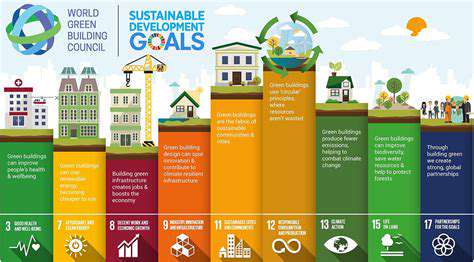

Global Standards and Local Action

While international frameworks like the Paris Agreement set broad targets, local building codes and zoning ordinances have proven more effective at driving actual decarbonization in real estate. Cities leading this charge are implementing requirements for energy benchmarking, electrification readiness, and circular construction practices.

Embracing Energy Efficiency as a Foundation

Optimizing Energy Consumption

The most cost-effective decarbonization measures often involve no technology at all - just smarter operations. Simple behavioral changes like nighttime temperature setbacks and daylight harvesting can yield 5-15% energy savings with zero capital investment. When combined with efficient equipment upgrades, savings often exceed 30%.

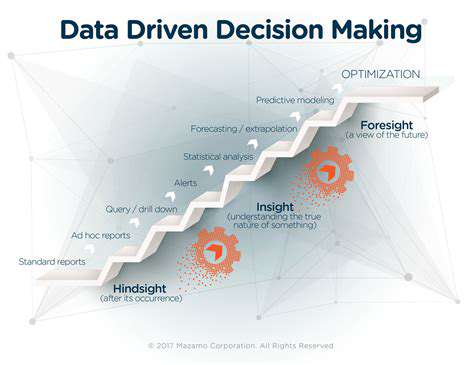

Technology-Enabled Efficiency

Modern building automation systems now leverage AI to predict and adapt to usage patterns. Machine learning algorithms can optimize energy use in real-time, achieving savings that manual systems simply can't match. Some newer platforms even integrate weather forecasting to pre-cool buildings before heat waves.

The Financial Case for Efficiency

While upfront costs concern many owners, energy efficiency upgrades typically pay for themselves within 3-7 years through operational savings. Innovative financing models like Property Assessed Clean Energy (PACE) programs remove even this barrier by tying repayment to the property tax bill.

Resilience Benefits

Efficient buildings aren't just cheaper to operate - they're more comfortable during power outages. High-performance envelopes maintain habitable temperatures far longer during grid failures, a critical advantage as climate disruptions increase. Some jurisdictions now prioritize efficiency upgrades as key climate adaptation measures.

Sustainable Materials and Construction Practices

Circular Materials Strategy

The construction industry's waste problem represents both a challenge and opportunity. Material reuse programs are turning demolition waste into valuable resources - one recent project achieved 98% diversion from landfill. Emerging digital platforms now connect material surpluses between job sites, creating a secondary market for construction materials.

Low-Carbon Material Innovations

Beyond recycled content, new material science breakthroughs are changing the game. Carbon-cured concrete actually absorbs CO2 during production, while mass timber construction stores carbon in building structures. These innovations are reshaping what's possible in sustainable construction.

Process Efficiency

Offsite construction methods like modular building can reduce material waste by 30-60% compared to traditional site-built approaches. Prefabrication also cuts construction timelines by 30-50%, reducing the carbon footprint of the construction process itself. These methods are particularly effective for repetitive building types like multifamily housing.