Pre Fabrication in Sustainable Real Estate Construction

Material Conservation in Off-Site Construction

Precision Engineering Reduces Resource Waste

Modern modular construction methods demonstrate remarkable efficiency in material usage. Factory-controlled production allows for exact measurements and optimized material cutting, virtually eliminating the staggering 30% waste typical of conventional construction sites. This systematic approach not only conserves resources but dramatically lowers the volume of construction debris destined for landfills.

The standardized design elements common in prefabricated buildings facilitate the use of regional materials. Local sourcing cuts transportation distances by an average of 60-80%, significantly reducing the carbon emissions associated with material delivery. Many manufacturers now maintain databases of nearby suppliers to streamline this sustainable practice.

Preserving Natural Sites Through Limited On-Site Work

Quieter, Cleaner Building Process

Traditional construction sites generate approximately 2.5 pounds of waste per square foot - modular methods slash this figure by up to 90%. The majority of assembly occurs in climate-controlled factories, meaning:

- Minimal heavy equipment on site

- Reduced soil compaction and erosion

- Lower noise pollution for neighboring areas

Construction timelines shrink by 30-50% with prefabrication, meaning shorter periods of disruption to local wildlife and communities. The condensed schedule also reduces the duration of temporary pollution sources like generators and portable toilets.

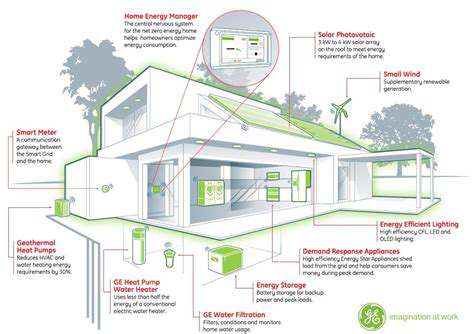

Energy-Smart Building From the Ground Up

Factory Integration of Green Technologies

Modular facilities allow for precise installation of energy-saving features that would be challenging on traditional job sites. Builders routinely incorporate:

- Laser-cut insulation with zero gaps

- Triple-pane windows installed in dust-free conditions

- Pre-wired renewable energy systems

These factory-integrated features typically reduce operational energy use by 15-20% compared to site-built structures. The controlled environment also enables rigorous quality checks that ensure each component meets exacting energy efficiency standards before shipment.

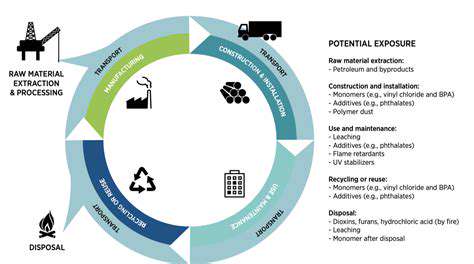

Closing the Loop With Circular Materials

Intentional Selection of Sustainable Resources

Forward-thinking manufacturers are transforming construction waste streams by:

- Specifying materials with 40-60% recycled content

- Implementing take-back programs for unused components

- Designing for future disassembly and material recovery

This circular approach can reduce a building's embodied carbon by up to 30%, while creating new markets for recycled construction materials. Some companies now use blockchain technology to track material origins and recycling potential throughout a structure's lifecycle.

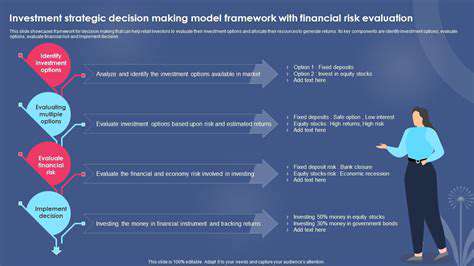

Financial Benefits of Modular Construction Methods

Strategic Cost Management Approaches

Eliminating Hidden Construction Expenses

The predictable nature of factory production allows for accurate cost forecasting rarely possible in conventional building. Material waste reduction alone saves 5-7% of total project costs, while streamlined logistics cut another 3-5% from budgets. These savings enable investment in higher-quality finishes or additional sustainable features.

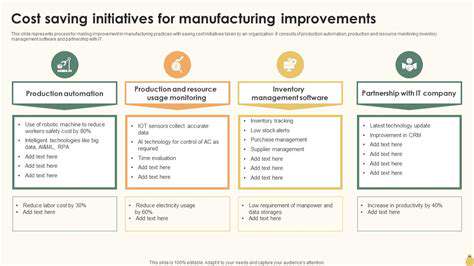

Lean Manufacturing Principles in Construction

Continuous Process Refinement

Modular facilities apply manufacturing best practices like:

- Just-in-time material delivery

- Standardized workstations

- Real-time quality monitoring

These methods reduce labor hours by 15-30% compared to site building, while simultaneously improving consistency. The repeatable processes also create opportunities for workforce specialization and faster training.

Smart Technology Integration

Automating for Accuracy and Speed

Advanced manufacturing equipment in modular plants includes:

- Robotic material handling systems

- Computer-controlled cutting tools

- Automated quality scanning

This technology reduces human error by up to 90% in critical tasks, virtually eliminating costly rework. The precision also allows for tighter tolerances that improve energy performance and longevity of the finished structures.

Read more about Pre Fabrication in Sustainable Real Estate Construction

Hot Recommendations

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy