Sustainable Construction Materials: An Overview

Exploring Common Sustainable Materials

Exploring the Rise of Recycled Plastics

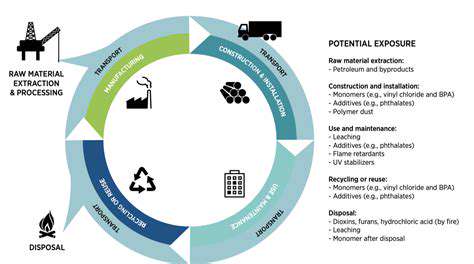

Across industries, there's a noticeable shift toward materials that support environmental sustainability. This movement is largely fueled by heightened awareness of ecological issues and the push for a circular economy. Among the most promising developments is the use of recycled plastics. By repurposing plastic waste, we significantly cut down on the need for new plastic production, which directly reduces fossil fuel consumption and landfill overflow. The process involves collecting discarded plastics, sorting them meticulously, and then transforming them into new, usable products.

However, the road to mainstream adoption isn't without bumps. Different plastic types demand specific recycling techniques, and even slight contamination can compromise the quality of the recycled output. Addressing these issues head-on is essential if we're to fully leverage recycled plastics as a cornerstone of sustainable material solutions. Continued innovation in sorting technologies and recycling methodologies will play a pivotal role in overcoming these hurdles.

Harnessing the Potential of Bio-Based Materials

Another frontier in sustainable materials is the development of bio-based alternatives sourced from renewable biological resources. These materials present an opportunity to move away from petroleum dependency while lessening environmental harm. Typically derived from agricultural byproducts or rapidly renewable plants, bio-based plastics contribute to a more sustainable production cycle.

Scaling these solutions remains challenging, particularly in terms of cost efficiency. Production methods need refinement to become economically viable on a large scale. Equally important is examining the complete environmental footprint of bio-based materials, from the farming stage through to end-of-life disposal. Factors like water consumption, land use changes, and emissions during manufacturing must all be part of this comprehensive evaluation.

Investigating the Properties of Wood-Based Composites

In construction and manufacturing, wood-based composites are emerging as a sustainable substitute for conventional materials. These engineered products combine wood fibers with other components to create materials that are strong, long-lasting, and visually appealing. Their adaptability allows for diverse applications across multiple industries.

The sustainability of these composites depends heavily on responsible sourcing practices. Unchecked wood harvesting can lead to deforestation and ecosystem disruption, so implementing sustainable forestry methods is non-negotiable. The entire production chain, from tree cultivation to final product disposal, must be designed with environmental stewardship in mind.

Exploring Advanced Composites and Nanomaterials

The materials science field is being transformed by breakthroughs in advanced composites and nanomaterials. These cutting-edge materials merge the best characteristics of different substances to deliver superior performance with reduced material requirements.

Realizing the full promise of these innovations requires substantial research funding and technological advancement. Scaling production while maintaining quality presents significant technical challenges that must be overcome. Additionally, we need thorough studies on the long-term environmental and health implications of these materials to ensure their safe use.

These technological leaps have the power to revolutionize entire industries, ushering in a new era of sustainable material innovation. Their continued development is crucial for building a greener future across all sectors.

Each of these sustainable material approaches offers distinct benefits and faces unique obstacles. When combined strategically, they present a comprehensive solution for reducing our environmental footprint while meeting modern material needs.

Assessing the Lifecycle of Building Materials

Understanding the Initial Stages

The planning and design phase of any construction project sets the trajectory for its entire lifespan. Decisions made during this stage about site preparation, regulatory compliance, and material choices profoundly influence the building's efficiency and durability. Investing time and resources in meticulous planning at this stage prevents expensive modifications later and ensures the final structure meets all operational requirements. These early choices also determine the building's environmental impact and energy consumption patterns for years to come.

Forward-thinking designs incorporate flexibility to accommodate future technological upgrades and changing user needs. Buildings designed with adaptability in mind can evolve with minimal disruption, extending their useful life and delaying obsolescence. This approach significantly enhances the long-term value of the property.

Construction and Occupancy

During construction, proper project management ensures the building takes shape according to specifications while staying within budget and timeline constraints. Effective coordination among all trades and strict quality control measures are essential for preventing issues that might surface during later phases. As the building becomes operational, real-world performance data provides invaluable insights into how well the design meets practical needs.

The occupancy phase offers opportunities to fine-tune systems and spaces based on actual user experiences. Regular occupant feedback helps identify areas where the building excels or falls short of expectations, informing future design improvements.

Maintenance and Repairs

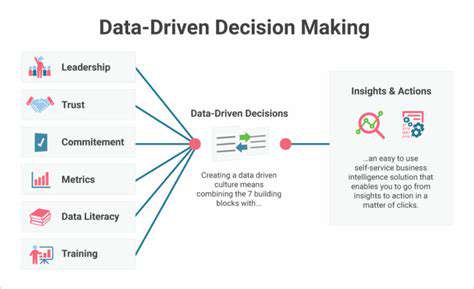

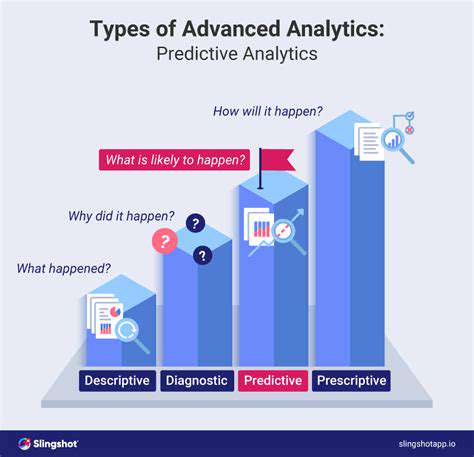

A well-structured maintenance program is the backbone of any building's longevity. Routine inspections and preventive maintenance catch small issues before they become major problems. Modern facilities are increasingly adopting predictive maintenance strategies that use data analytics to forecast when components might fail, allowing for timely intervention.

Consistent upkeep not only preserves the building's structural soundness but also maintains its market value and visual appeal. Proper maintenance protocols ensure the safety of occupants while protecting the owner's investment over the long term.

Renovation and Modernization

As buildings age or requirements change, strategic renovations breathe new life into existing structures. These projects must balance modernization with respect for the original design intent. Thoughtful renovation planning maximizes the benefits of upgrades while minimizing disruption and unnecessary costs. Many renovation projects now focus on improving energy efficiency and sustainability features to meet current environmental standards.

Demolition and Redevelopment

When a building reaches the end of its useful life, responsible deconstruction becomes paramount. Modern demolition practices emphasize material recovery and recycling to minimize waste. Safety protocols protect workers and the surrounding community during the dismantling process.

Redevelopment decisions should carefully weigh the potential for adaptive reuse against the benefits of new construction. Comprehensive environmental impact assessments ensure that whatever follows the demolition aligns with sustainable development principles and community needs. This holistic approach to the building lifecycle creates a framework for more responsible construction practices industry-wide.

Read more about Sustainable Construction Materials: An Overview

Hot Recommendations

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy