Modular Sustainable Housing: Future of Affordable Homes

Prefabrication: A Modern Approach to Construction

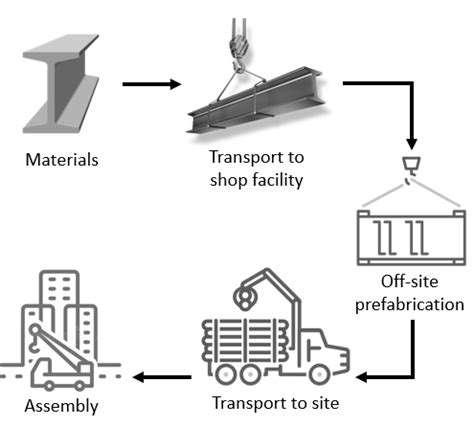

Prefabrication, the process of assembling building components in a controlled factory environment, is rapidly transforming the construction industry. This approach offers numerous advantages over traditional on-site construction methods, ultimately leading to faster project timelines and improved quality control.

Prefabrication allows for more efficient use of resources, reducing waste and minimizing environmental impact. The standardized nature of prefabricated components ensures that materials are used effectively and precisely, leading to a more sustainable construction process.

Optimized Project Schedules

One of the most significant benefits of prefabrication is the ability to significantly shorten project timelines. By assembling components off-site in a controlled environment, construction can proceed more quickly on-site. This streamlined approach can result in considerable cost savings and reduced project delays.

Enhanced Quality Control

Prefabrication allows for rigorous quality control measures to be implemented during the manufacturing process. This is often more effective than relying on on-site inspections, leading to a higher-quality final product. The controlled environment of the factory facilitates precise measurements and adherence to specifications, reducing the potential for errors.

Reduced Construction Site Challenges

Prefabricated components often arrive on-site fully assembled or ready for immediate installation. This minimizes the need for complex on-site assembly, leading to a more organized and efficient construction process. This minimizes the risk of weather delays and other unforeseen problems, making project delivery more predictable.

Improved Safety on Construction Sites

Prefabrication often involves less complex on-site assembly, which can lead to fewer hazards and a safer work environment for construction workers. This reduced risk of accidents and injuries can lead to a more productive and safe construction process. A more controlled environment during the manufacturing process also improves safety by reducing the risk of accidents in the manufacturing plant.

Cost Savings and Efficiency

Prefabrication can lead to considerable cost savings throughout the construction lifecycle. By minimizing on-site labor and material waste, prefabrication can significantly reduce overall project expenses. The reduced labor costs and the possibility of using off-site manufacturing facilities for components can lead to significant cost reductions.

Sustainable Construction Practices

Prefabricated construction methods often align better with sustainable building practices. The controlled environment of prefabrication allows for the use of sustainable materials and the implementation of efficient waste management systems. This commitment to sustainability can reduce the environmental footprint of construction projects. By reducing waste and employing sustainable materials, prefabrication can contribute to environmentally friendly construction practices.

Sustainable Materials and Practices: Eco-Conscious Construction

Choosing Sustainable Materials

Sustainable materials are crucial for eco-conscious construction. Prioritizing materials with a low environmental impact throughout their lifecycle is paramount. This includes considering the sourcing, manufacturing, and disposal processes. Wood from responsibly managed forests, recycled steel, and concrete made with fly ash are excellent examples of sustainable alternatives to traditional materials. Careful consideration must be given to the embodied energy of each material, as well as its potential for reuse or recycling at the end of its lifespan.

Furthermore, the selection of materials should also account for their durability and longevity. Using high-quality, long-lasting materials reduces the need for frequent replacements, thereby minimizing waste and resource consumption. This approach not only contributes to a more sustainable building but also saves money in the long run.

Implementing Eco-Friendly Construction Practices

Eco-conscious construction extends beyond material selection. Implementing sustainable practices throughout the construction process is equally important. This involves using water-efficient fixtures, minimizing waste generation on-site, and adopting strategies for reducing energy consumption. For example, utilizing prefabrication techniques can significantly reduce construction waste and minimize disruption to the surrounding environment.

Adopting green building certifications, such as LEED, is another essential step in ensuring sustainability. These certifications establish standards and guidelines for environmentally responsible construction practices, ensuring that every aspect of the project aligns with sustainability goals. Moreover, prioritizing local and regional materials can significantly reduce transportation emissions and support local economies.

Modular Construction for Reduced Waste

Modular construction offers a unique opportunity to significantly reduce waste in the building process. Pre-fabricated components are assembled in a controlled factory environment, minimizing on-site waste and material loss. This method also leads to faster construction times and potentially lower labor costs. The precise planning and controlled environment of modular construction allow for more efficient material use, reducing excess and optimizing resource allocation.

The standardized nature of modular construction also lends itself well to the use of recycled and reclaimed materials. Components can be designed with built-in opportunities for disassembly and reuse, contributing to a circular economy approach. This approach to construction minimizes the environmental impact of the entire project lifecycle, from material sourcing to demolition.

Sustainable Design and Energy Efficiency

Sustainable design principles are integral to eco-conscious construction. This includes optimizing building orientation for natural light and ventilation, incorporating energy-efficient windows and insulation, and utilizing renewable energy sources. Smart technologies can play a critical role in monitoring and managing energy consumption, leading to significant reductions in operational costs and environmental impact.

Designing for adaptability and future needs is also a key element. Buildings should be designed to be easily modified or adapted to changing needs or technologies, reducing the need for costly and disruptive renovations. Incorporating features like flexible layouts and adaptable spaces helps ensure that the building can remain functional and efficient over its lifespan.

Read more about Modular Sustainable Housing: Future of Affordable Homes

Hot Recommendations

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy