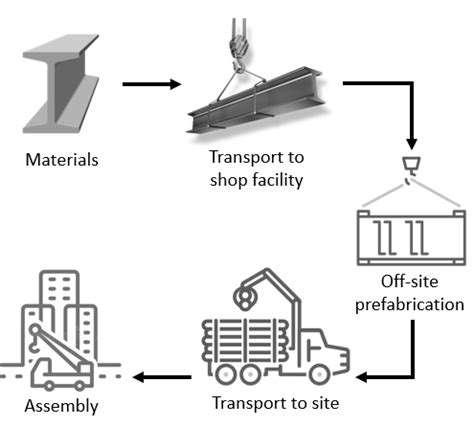

Pre Fabrication in Sustainable Real Estate Development

Consider these real-world numbers from recent projects:- 22% reduction in concrete costs through precast slab systems- 41% less drywall waste using panelized wall systems- 67% decrease in electrical wiring materials with pre-fabricated raceways

The financial implications are substantial. A 200,000 sq.ft. commercial development saved $1.2 million simply by pre-cutting all structural steel components - eliminating field modifications and scrap. These aren't theoretical benefits but documented results from projects adopting prefabrication at scale.

Design Innovation Through Modular Construction

Breaking Conventional Design Barriers

Contemporary architects are leveraging prefabrication to achieve what was previously structurally or financially unfeasible. The 30 Hudson Yards cantilever in New York - extending 65 feet beyond its base - was made possible through precisely engineered steel modules fabricated off-site. This exemplifies how prefabrication enables daring architectural statements while maintaining structural integrity.

Hospital design provides another compelling case. Modern healthcare facilities require intricate MEP (mechanical, electrical, plumbing) systems that would be chaotic to install conventionally. By pre-assembling entire patient room chassis with all systems integrated, hospitals like the Kaiser Permanente Modesto Medical Center reduced construction time by 40% while improving system coordination.

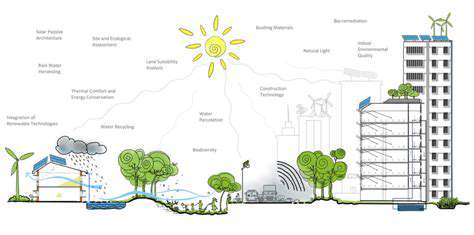

The Sustainability Equation

Prefabrication's environmental benefits extend beyond waste reduction. Factory conditions enable:- Precise insulation installation (achieving R-30 ratings vs. R-22 in field-built walls)- Tighter building envelopes (reducing air leakage by up to 73%)- Integration of recycled materials (up to 89% recycled content in some structural components)

The numbers tell the story: a DOE study found prefabricated buildings consume 17% less energy over their lifespan compared to conventionally constructed counterparts. When the Bullitt Center in Seattle - the world's greenest commercial building - incorporated prefabricated cross-laminated timber panels, it achieved both sustainability goals and accelerated its ambitious timeline.

Labor and Safety Advancements in Prefab Construction

Workforce Transformation

The construction labor shortage (projected at 1 million workers by 2025) makes prefabrication's labor efficiencies crucial. A single factory technician can produce work equivalent to 3-5 field workers, according to McGraw-Hill research. This productivity multiplier stems from:

- Specialized workstations reducing movement waste- Automated equipment handling repetitive tasks- Continuous workflow unaffected by weather or site conditions

Safety statistics are equally compelling. OSHA data shows injury rates in fabrication facilities are 82% lower than construction sites. The controlled environment eliminates falls (responsible for 36% of construction fatalities) and reduces exposure to hazardous materials. For example, welding in a ventilated factory booth versus an enclosed job site cuts fume exposure by 94%.

Urban Development Acceleration

Consider these impacts on housing shortages:- Modular construction enabled the Stack modular apartments in Brooklyn to rise 32 stories in just 45 days of on-site work- Singapore's HDB program delivers 25,000 prefabricated housing units annually- A London developer completed a 44-story tower in 19 weeks using 90% prefabricated components

The implications for urban planners are profound. Where traditional methods might deliver 50 units per year on a given site, prefabrication can triple that output. This scalability makes prefabrication not just an option but a necessity for addressing global urbanization challenges.