Circular Economy Principles in Sustainable Development

Shifting to circular systems presents immense advantages: reduced ecological damage, greater resource security, and fresh economic possibilities. Cutting waste and pollution helps preserve ecosystems while combating climate change. The economic upside is particularly compelling, as circular models create entirely new markets around reclaimed materials and innovative services.

Yet significant hurdles remain. The transformation requires substantial investments in new technologies, infrastructure upgrades, and public education campaigns. Perhaps most challenging is the need for cultural change - businesses, governments, and individuals must all rethink entrenched habits and processes. Additional barriers include inconsistent regulations across regions, technological limitations in material recovery, and resistance from industries benefiting from the status quo.

Despite these challenges, the case for circularity grows stronger daily. With coordinated effort and long-term commitment, we can overcome these obstacles to build an economic system that works in harmony with our planet's limits.

Optimizing Resources and Reducing Waste

Strategic Approaches to Waste Reduction

Effective waste management forms the backbone of circular economic models. Comprehensive strategies range from preventing waste generation at the source to maximizing material recovery through recycling and composting. Success requires tailored solutions that account for local contexts - analyzing current waste patterns, identifying reduction opportunities, and implementing targeted management plans. Public education plays a pivotal role in changing behaviors at both individual and organizational levels.

The most impactful solutions address waste prevention at the design stage. By creating products with longevity and recyclability in mind, manufacturers can dramatically decrease waste volumes. This approach benefits from partnerships between businesses and material scientists to develop sustainable alternatives. Forward-thinking design doesn't just help the environment - it often reduces long-term costs by minimizing disposal needs.

Revolutionizing Material Recovery

Advanced recycling systems are transforming waste streams into valuable resources. Modern facilities can extract and purify materials with remarkable efficiency, reducing landfill dependence while conserving finite natural resources. The key lies in establishing robust collection networks and sorting infrastructure that maintain material quality throughout the process.

Successful programs typically involve collaboration between public agencies, private companies, and community organizations. Easy-to-use recycling systems combined with clear public messaging boost participation rates. Creating market demand for recycled content through procurement policies and manufacturing incentives completes the circular loop.

Designing for the Future

The circular economy begins at the drawing board. Products designed for easy disassembly allow components to be repurposed rather than discarded. This approach significantly reduces the need for virgin materials while minimizing waste generation.

Building durable goods extends product lifecycles, decreasing the frequency of replacement purchases and their associated environmental costs. This means selecting premium materials, employing superior manufacturing techniques, and supporting products with comprehensive maintenance services throughout their usable life.

Assessing Environmental Impact

Comprehensive life cycle analysis provides crucial insights into a product's environmental footprint from cradle to grave. These assessments reveal opportunities to reduce resource use and waste at every stage. Understanding these impacts enables smarter decisions about materials, production methods, and end-of-life management.

The data from these studies helps companies develop more sustainable products and supports the broader transition to circular economic models. It provides the evidence needed to justify design changes and process improvements that benefit both business and environment.

Changing Consumption Patterns

Transforming how we consume is equally important as changing how we produce. Encouraging thoughtful purchasing decisions, supporting sustainable businesses, and normalizing repair culture all contribute to reduced material consumption. Consumer behavior changes can drive market transformations when supported by clear information and accessible alternatives.

Policy measures can accelerate this shift through mechanisms like product labeling schemes, repair subsidies, and taxes on single-use items. When consumers understand the environmental consequences of their choices, they're more likely to adopt sustainable habits.

Building Collaborative Frameworks

Effective resource management requires coordination across sectors. Partnerships between government, industry, academia, and communities facilitate knowledge exchange and innovation. Aligning policies and initiatives creates the supportive ecosystem needed for circular models to thrive.

Strategic policy instruments - from extended producer responsibility laws to waste reduction targets - create the conditions for sustainable business practices. These measures help level the playing field so that environmentally responsible companies can compete effectively.

Implementing Circular Systems: A Comprehensive Strategy

Putting Principles into Practice

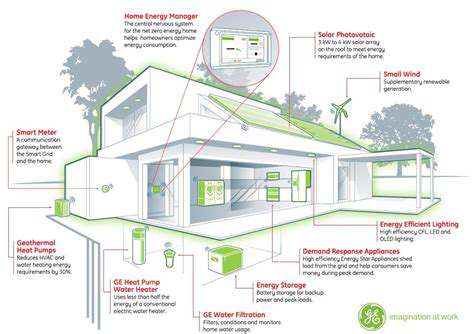

The shift from linear to circular models represents a fundamental transformation in how we create and consume. Implementing circular economy principles means redesigning products for longevity, ease of repair, and eventual recycling. This requires rethinking traditional business models and supply chain relationships across industries. Companies embracing these changes often discover new revenue streams while reducing their environmental liabilities.

Advancing Material Recovery

Modern recycling goes far beyond basic sorting - it's about maximizing the value recovered from used materials. Sophisticated processing techniques can yield high-quality recycled content that competes with virgin materials. Investment in advanced sorting technologies and processing facilities is critical to achieving these results at scale.

Designing for Circularity

The most sustainable product is one that never becomes waste. Designing for durability and reusability extends product lifecycles, reducing the frequency of replacement purchases. When products are built to be repaired and refurbished, they generate significantly less waste over their lifetime. This approach also creates new business opportunities in maintenance, refurbishment, and resale markets.

Transforming Supply Networks

Circular supply chains prioritize sustainable sourcing and minimal environmental impact. Partnering with suppliers committed to responsible practices ensures materials enter the system with the smallest possible footprint. Visibility across the supply chain is essential for verifying sustainability claims and identifying improvement opportunities. Digital tracking technologies now make this level of transparency achievable.

Engaging Consumers

Successful circular systems require active consumer participation. Educating buyers about the benefits of durable, repairable products creates demand for sustainable options. When consumers understand how their choices affect the environment, they're more likely to support circular business models. Initiatives that make repair convenient and affordable can significantly shift consumption patterns.

Policy Foundations

Government action can accelerate the circular transition through well-designed regulations and incentives. Measures like extended producer responsibility laws and green procurement policies create favorable conditions for circular businesses. Clear, consistent regulations help align industry practices with environmental priorities. Policy frameworks that internalize environmental costs make sustainable choices more economically attractive.

Financial Innovation

The transition requires new financial models that reward circular outcomes. Product-as-service arrangements, where customers pay for access rather than ownership, align business incentives with resource efficiency. Investments in circular technologies and infrastructure can yield both environmental and economic returns. Financial instruments that account for sustainability performance help redirect capital toward circular solutions.