The Future of Real Estate: AI Driven Innovation

Predictive maintenance, driven by advancements in artificial intelligence (AI), is revolutionizing industrial operations by moving beyond reactive and preventative maintenance strategies. This proactive approach focuses on anticipating equipment failures before they occur, minimizing downtime and maximizing operational efficiency. By leveraging vast amounts of data and sophisticated algorithms, AI enables a deeper understanding of equipment health, allowing for proactive interventions and optimized maintenance schedules. This shift leads to significant cost savings and improved safety within industrial settings.

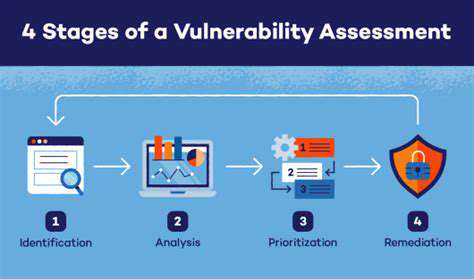

The core principle behind AI-driven predictive maintenance is the analysis of real-time data from various sources, including sensors, historical maintenance records, and operational logs. This data is then processed and analyzed by sophisticated algorithms to identify patterns, anomalies, and potential failure points in equipment. The insights gained from this analysis enable the development of predictive models that forecast potential failures.

Data Collection and Integration: The Foundation of AI-Powered Solutions

Effective predictive maintenance relies heavily on the quality and quantity of data collected from various sources within the industrial environment. This data often comes from sensors embedded in machinery, providing real-time information on vibration, temperature, pressure, and other critical parameters. Integrating this data with historical maintenance records and operational logs provides a comprehensive view of equipment performance over time.

Integration of disparate data sources can be complex, requiring robust data pipelines and standardization protocols. The goal is to create a unified data platform that enables AI algorithms to access and process all relevant information efficiently. This integration is crucial for accurate predictions and optimized maintenance scheduling.

AI Algorithms: Unlocking Predictive Capabilities

A variety of AI algorithms are employed in predictive maintenance, including machine learning (ML) models such as regression, classification, and clustering. These algorithms learn from historical data to identify patterns and anomalies, ultimately enabling accurate predictions of potential equipment failures. Deep learning models, especially neural networks, are also increasingly used for their ability to handle complex data relationships and extract intricate patterns.

Real-Time Monitoring and Alerting: Ensuring Proactive Responses

AI-powered predictive maintenance systems continuously monitor equipment performance in real time. This real-time monitoring allows for the rapid identification of deviations from normal operating parameters, enabling proactive intervention before critical failures occur. Real-time alerts are crucial for notifying maintenance personnel of potential issues, enabling them to schedule maintenance promptly and prevent costly breakdowns.

Optimized Maintenance Scheduling: Maximizing Efficiency

Predictive maintenance models provide insights into the optimal time for maintenance activities. By analyzing data and forecasting potential failures, these models enable the development of optimized maintenance schedules that minimize downtime and maximize equipment uptime. This proactive approach allows for preventative maintenance to be performed at the most opportune moment, reducing unexpected disruptions and improving overall efficiency.

Cost Savings and Return on Investment (ROI): A Key Driver

AI-driven predictive maintenance delivers significant cost savings by reducing unplanned downtime, minimizing costly repairs, and optimizing maintenance schedules. Predictive maintenance can also reduce maintenance costs by enabling proactive interventions, preventing catastrophic failures, and reducing the frequency of unscheduled repairs. The return on investment (ROI) from implementing such systems is often substantial, making it a compelling investment for industrial organizations.

The Future of Predictive Maintenance: Emerging Trends

The field of predictive maintenance is constantly evolving, with emerging trends such as the integration of the Internet of Things (IoT) and the use of edge computing. IoT devices provide real-time data from remote locations, while edge computing processes data closer to the source, enhancing speed and efficiency. These advancements will further enhance the capabilities of predictive maintenance, leading to even more precise predictions and optimized maintenance strategies.