Zero Waste Construction: Policy and Incentives

Measuring and Monitoring Progress: Key Performance Indicators

Defining Key Performance Indicators (KPIs)

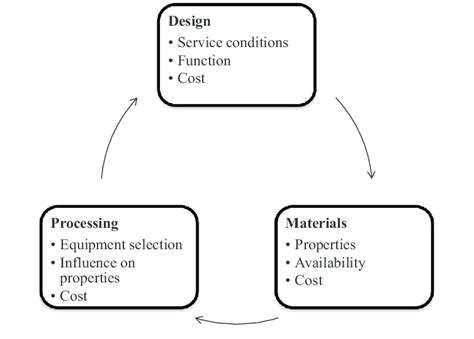

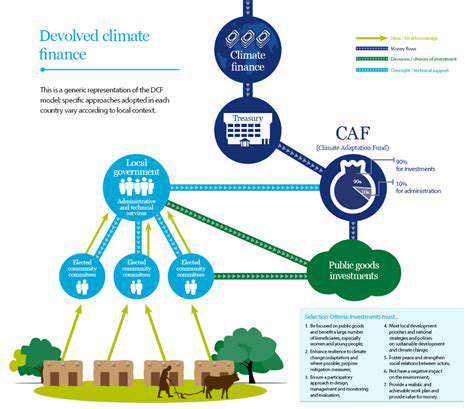

In the context of zero-waste construction, KPIs are quantifiable metrics used to track progress towards sustainability goals. These indicators provide objective data on the effectiveness of implemented strategies and highlight areas needing improvement. Choosing the right KPIs is crucial; they should align with specific project objectives and reflect the unique characteristics of the construction site and the project's scope. For example, a key KPI might be the reduction in landfill waste per square meter of construction, or the percentage of recycled materials incorporated into the project.

Tracking Material Waste Reduction

A critical KPI in zero-waste construction is the reduction of material waste. This involves meticulously tracking the amount of materials used against the planned quantities. Detailed records of material consumption, including the type, quantity, and source of each material, are essential for identifying patterns and pinpointing areas for improvement. By analyzing waste streams, construction teams can learn which materials are frequently wasted and implement strategies to minimize these losses. This might involve optimizing material ordering, improving storage practices, or utilizing construction techniques that minimize material cut-offs.

Monitoring Recycled Content Incorporation

Quantifying the percentage of recycled materials incorporated into the project is a vital KPI. This involves tracking the amount of recycled materials used in construction materials and the total amount of materials used in the construction process. Accurate data collection and reporting are paramount in demonstrating the project's commitment to sustainability and in measuring the effectiveness of recycling initiatives. This includes specifying recycled content requirements in material procurement and ensuring proper documentation of the source and type of recycled materials used.

Assessing Energy Consumption

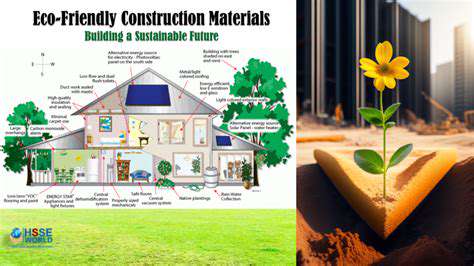

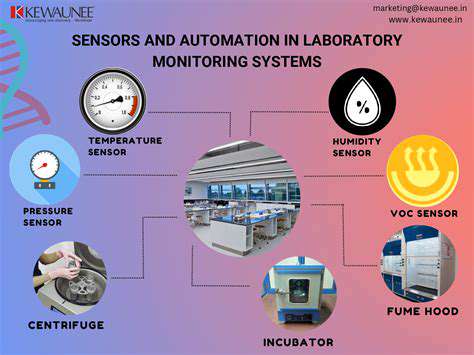

Energy consumption during construction can have a significant environmental impact. Monitoring energy usage through detailed records of energy consumption by specific equipment and activities is crucial. This data allows for identification of areas where energy efficiency can be improved. For instance, optimizing equipment operation schedules, implementing more energy-efficient machinery, and utilizing renewable energy sources can all contribute to a reduction in energy consumption and to a positive environmental impact. Analyzing the data helps pinpoint opportunities for optimizing energy use.

Evaluating Water Usage Efficiency

Water conservation is a significant aspect of sustainable construction. Tracking water usage during various construction phases, and comparing it to baseline data, is an important KPI. This involves recording water consumption by specific tasks, such as concrete mixing, site cleaning, and worker hydration. Implementing water-efficient technologies and practices, such as rainwater harvesting and efficient irrigation systems, are essential for minimizing water usage and ensuring responsible water management on the construction site. By analyzing these metrics, the project can demonstrate its commitment to water conservation.

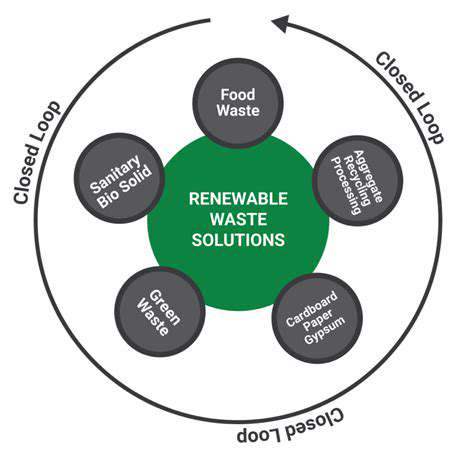

Measuring Construction Site Waste Diversion Rates

A key measure of zero-waste construction success is the diversion rate of construction and demolition (C&D) waste from landfills. This KPI tracks the percentage of waste diverted from landfills through recycling, reuse, or composting. This requires meticulous tracking of the amount of waste generated at the site, as well as the specific methods used for diverting it from the landfill. Establishing clear protocols for waste sorting, partnering with local recycling facilities, and promoting proper waste management practices are essential for achieving high diversion rates. By consistently monitoring this metric, the project can demonstrate its commitment to reducing landfill burden.

Analyzing Project Cost-Effectiveness of Zero-Waste Practices

Evaluating the financial implications of zero-waste initiatives is crucial. Comparing the initial investment in zero-waste strategies to the long-term cost savings from reduced waste disposal, material costs, and potential incentives should be done. This requires careful tracking of the costs associated with implementing various zero-waste practices, including material sourcing, waste management, and staff training. The analysis should also consider any potential cost savings associated with reduced environmental impact, such as lower fines or penalties for exceeding waste disposal limits. This crucial evaluation helps justify the long-term viability of zero-waste construction strategies.

Read more about Zero Waste Construction: Policy and Incentives

Hot Recommendations

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy