Modular Construction for Sustainable Real Estate

Improved Quality Control

Factory-based prefabrication enables rigorous quality assurance protocols that consistently produce superior construction outcomes. Standardized components manufactured with exact precision ensure uniform quality across all building elements, significantly reducing defects and construction errors. This methodical approach to quality management yields exceptionally durable and reliable structures. The controlled manufacturing environment also facilitates the implementation of advanced building materials and innovative construction techniques, further enhancing overall build quality.

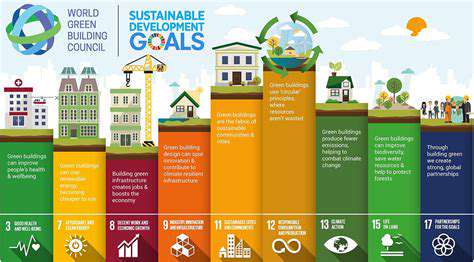

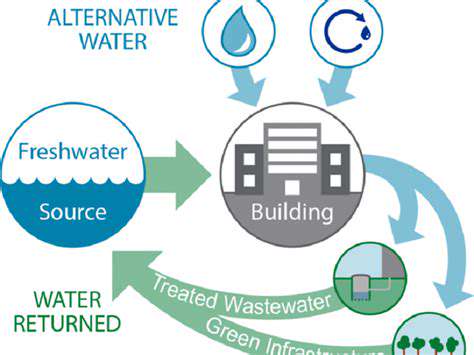

Sustainable Practices

Modular construction naturally incorporates numerous environmentally responsible practices throughout the building process. Reduced on-site waste generation, optimized material usage, and minimized transportation requirements all contribute to a smaller ecological footprint. The factory setting allows for consistent implementation of sustainable materials and eco-friendly construction methods, aligning with growing market demand for green building solutions. These sustainable attributes make modular construction particularly appealing for environmentally conscious development projects.

Enhanced Design Flexibility

The modular approach offers architects and designers remarkable creative freedom compared to conventional construction techniques. Prefabrication accommodates complex designs and customized components that might prove impractical or prohibitively expensive in traditional building projects. This adaptability proves especially valuable for structures requiring distinctive architectural features or specialized functional elements, allowing for truly unique building solutions.

Reduced Risk and Project Management

Modular construction delivers more predictable project schedules with fewer uncertainties than traditional building methods. All prefabricated components undergo thorough testing and inspection before leaving the factory, minimizing on-site complications and schedule disruptions. The standardized nature of modular elements simplifies coordination among all project stakeholders, facilitating clearer communication and more efficient project management. This enhanced schedule reliability creates a less stressful and more manageable experience for everyone involved in the construction process.

Improved Quality and Design Flexibility

Enhanced Visual Appeal

Superior construction quality naturally results in more aesthetically pleasing final products, particularly in architectural design. High-grade materials and refined construction techniques enable more sophisticated visual outcomes, giving designers greater creative license without sacrificing durability or functionality. This elevated design language proves essential for creating distinctive buildings that enhance brand identity and market appeal.

The inherent design flexibility of modular construction allows for highly customized solutions tailored to specific user needs and preferences, ultimately delivering more satisfying occupant experiences. This personalization capability frequently translates to increased user satisfaction and stronger brand allegiance over time.

Expanded Design Possibilities

With quality materials and construction methods, architects overcome many limitations imposed by conventional building materials. This liberation unlocks unprecedented creative potential, enabling designers to explore innovative forms, textures, and color applications. The ability to experiment freely results in truly distinctive architectural expressions that stand out in the built environment.

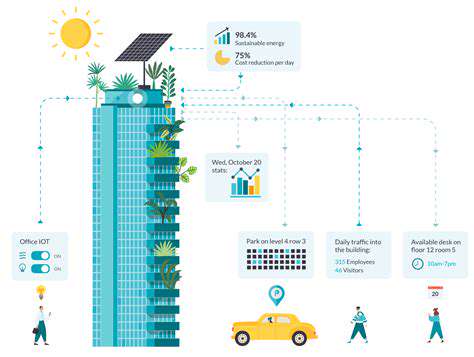

This design flexibility extends to seamless integration of advanced features and smart technologies. Buildings can be designed to interact intelligently with other systems, providing occupants with sophisticated, interconnected environments that anticipate and respond to their needs - a crucial advantage in today's technology-driven marketplace.

Streamlined Manufacturing Processes

Enhanced quality stems in part from optimized manufacturing procedures that reduce errors, minimize waste, and boost production efficiency. These improvements directly impact overall project economics, enabling competitive pricing while maintaining exceptional quality standards.

The adaptable nature of modular manufacturing allows for responsive adjustments during production, making it easier to accommodate evolving market trends or specific client requests. This agility provides a significant competitive advantage in today's rapidly changing business environment.

Cost-Effectiveness and Efficiency

While premium quality might suggest higher initial costs, the long-term benefits frequently justify the investment. Refined processes and reduced waste lead to greater operational efficiency and eventual cost savings - critical factors in maintaining profitability.

Superior quality and design flexibility produce buildings that endure, reducing the need for frequent renovations or replacements. This longevity generates substantial savings for both building owners and occupants over time, distinguishing such projects in a market often dominated by short-term cost considerations.

Sustainable Design Practices

The emphasis on quality and flexibility naturally extends to sustainable building practices. Modular construction readily incorporates eco-friendly materials, responsible sourcing, and minimal environmental impact throughout the building lifecycle. These sustainable practices not only demonstrate environmental responsibility but also strengthen brand perception among increasingly eco-conscious consumers.

The design flexibility inherent in modular construction facilitates buildings that are both visually striking and environmentally responsible. Features promoting durability and ease of maintenance are integrated into designs, reducing waste and extending building lifespans. This forward-thinking approach contributes to a more sustainable future by decreasing consumption patterns and emphasizing long-term value over disposable solutions.