AI Driven Valuation: A Game Changer for the Real Estate Industry

Leveraging Machine Learning for Predictive Power

Leveraging Machine Learning for Predictive Maintenance

Machine learning (ML) algorithms are revolutionizing various industries, and predictive maintenance is one prominent area of application. By analyzing historical data, ML models can identify patterns and anomalies that indicate potential equipment failures before they occur. This proactive approach allows businesses to schedule maintenance proactively, minimizing downtime and maximizing equipment lifespan.

Predictive maintenance using ML often involves the use of sensors and other data collection methods to gather real-time data about equipment performance. This data is then fed into machine learning models to identify patterns and predict potential failures. This approach offers significant cost savings and improved operational efficiency.

Data Collection and Preparation

A crucial aspect of successful ML-based predictive maintenance is the quality and quantity of data used to train the models. This involves meticulously collecting data from various sources, including sensor readings, operational logs, and maintenance records. Thorough data cleaning and preprocessing techniques are essential to ensure that the data is accurate, consistent, and suitable for model training.

Careful consideration should be given to the selection of relevant features. Including irrelevant or noisy data can negatively impact model accuracy. Data preparation often involves handling missing values, transforming data types, and normalizing data ranges.

Model Selection and Training

Choosing the right machine learning model is critical for achieving accurate predictions. Different models are suitable for different types of data and prediction tasks. For example, regression models are often used to predict the remaining useful life of equipment, while classification models can be used to identify potential failures.

The training process involves feeding the prepared data into the selected model to learn patterns and relationships. The model's parameters are adjusted iteratively to optimize its performance. Careful evaluation of the model's accuracy and performance on a separate test dataset is necessary to ensure its reliability in real-world applications.

Monitoring and Evaluation

Predictive maintenance systems are not static; they require ongoing monitoring and evaluation to ensure continued accuracy. As new data becomes available, the models need to be retrained to adapt to changes in equipment performance and operating conditions.

Regular performance monitoring and analysis of predictions are crucial to identify any degradation in model accuracy or identify new trends in the data. This allows for timely adjustments and ensures that the predictive maintenance system remains effective over time.

Deployment and Integration

Successfully implementing predictive maintenance systems requires careful integration into existing workflows and infrastructure. This includes establishing clear communication channels between the system and maintenance teams, integrating data from various sources, and providing user-friendly interfaces for monitoring and interacting with the system.

Integrating the ML models into existing maintenance management systems is essential for seamless operation. This allows technicians to access predictions, schedule maintenance tasks, and track performance in a centralized platform.

Cost Savings and Benefits

The benefits of implementing machine learning for predictive maintenance are significant. Reduced downtime and minimized maintenance costs are key advantages, allowing businesses to optimize their operations and improve profitability. The ability to predict failures proactively avoids costly unplanned repairs and ensures equipment reliability.

Improved safety and productivity are other notable benefits. By preventing unexpected equipment failures, ML-driven predictive maintenance minimizes risks and enhances overall operational efficiency.

Read more about AI Driven Valuation: A Game Changer for the Real Estate Industry

Hot Recommendations

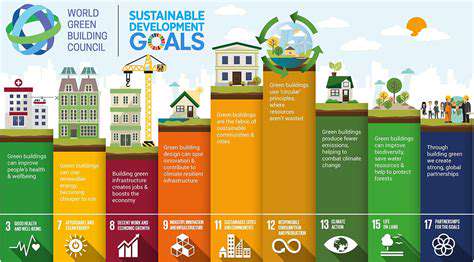

- Sustainable Real Estate Design Principles

- AI in Real Estate: Streamlining the Buying Process

- Climate Risk Disclosure: A Must for Real Estate

- Climate Risk Analytics: Essential for Real Estate Investment Funds

- Modular Sustainable Construction: Scalability and Speed

- Real Estate and Community Disaster Preparedness

- Smart Buildings and Advanced Building Analytics for Optimal Performance

- Smart Waste Sorting and Recycling in Buildings

- Sustainable Real Estate: A Strategic Advantage

- AI in Real Estate Transaction Processing: Speed and Accuracy